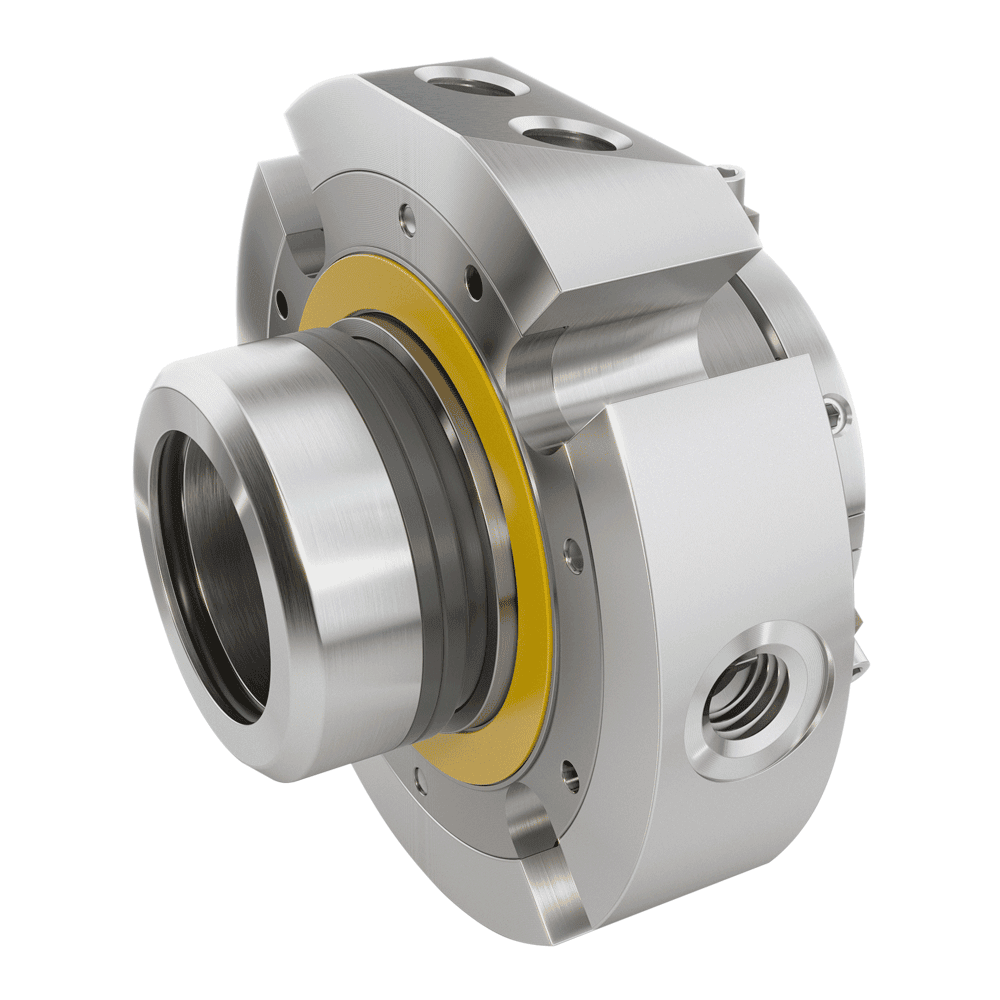

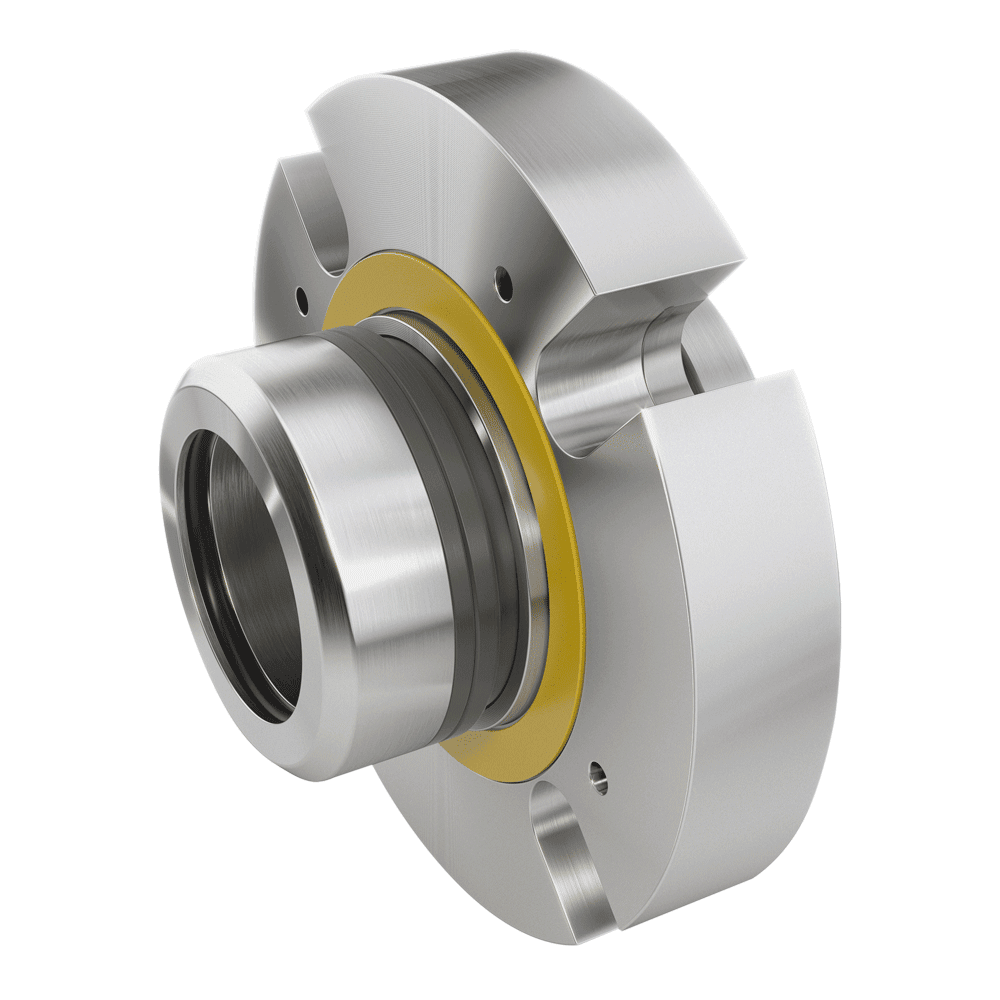

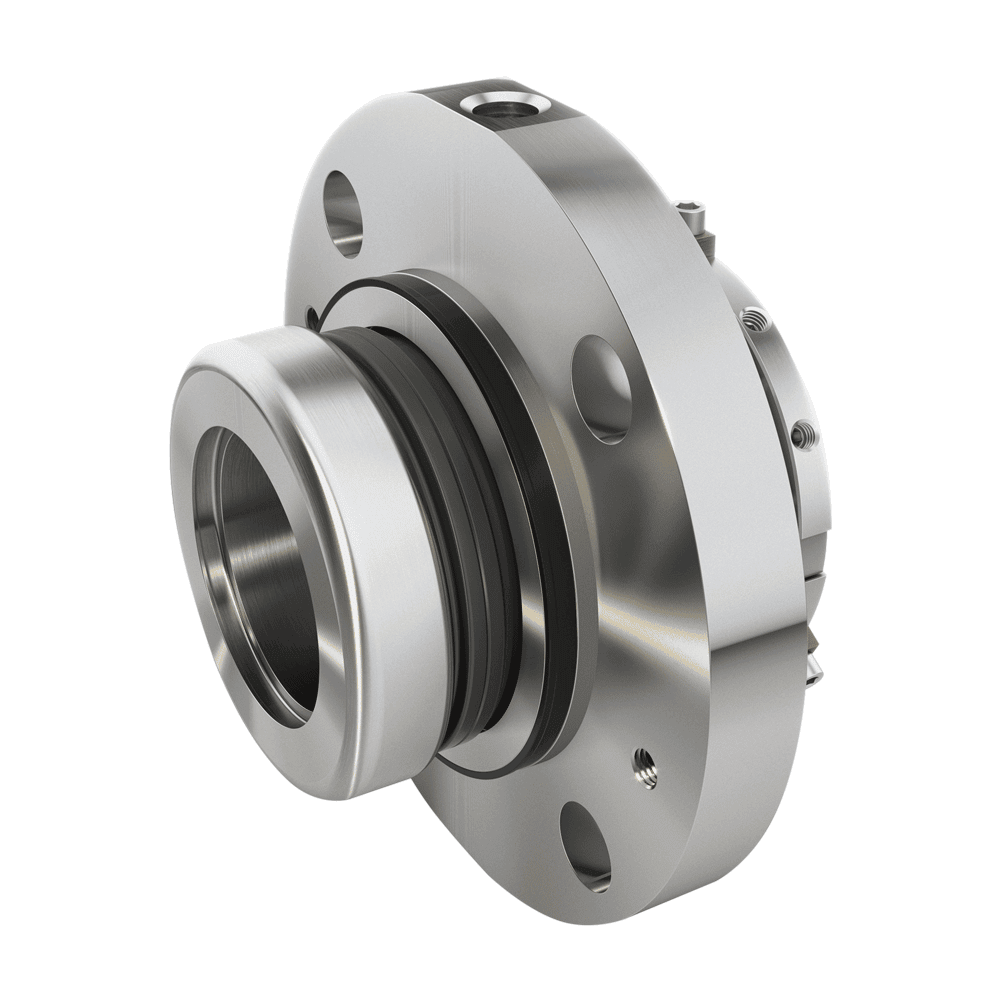

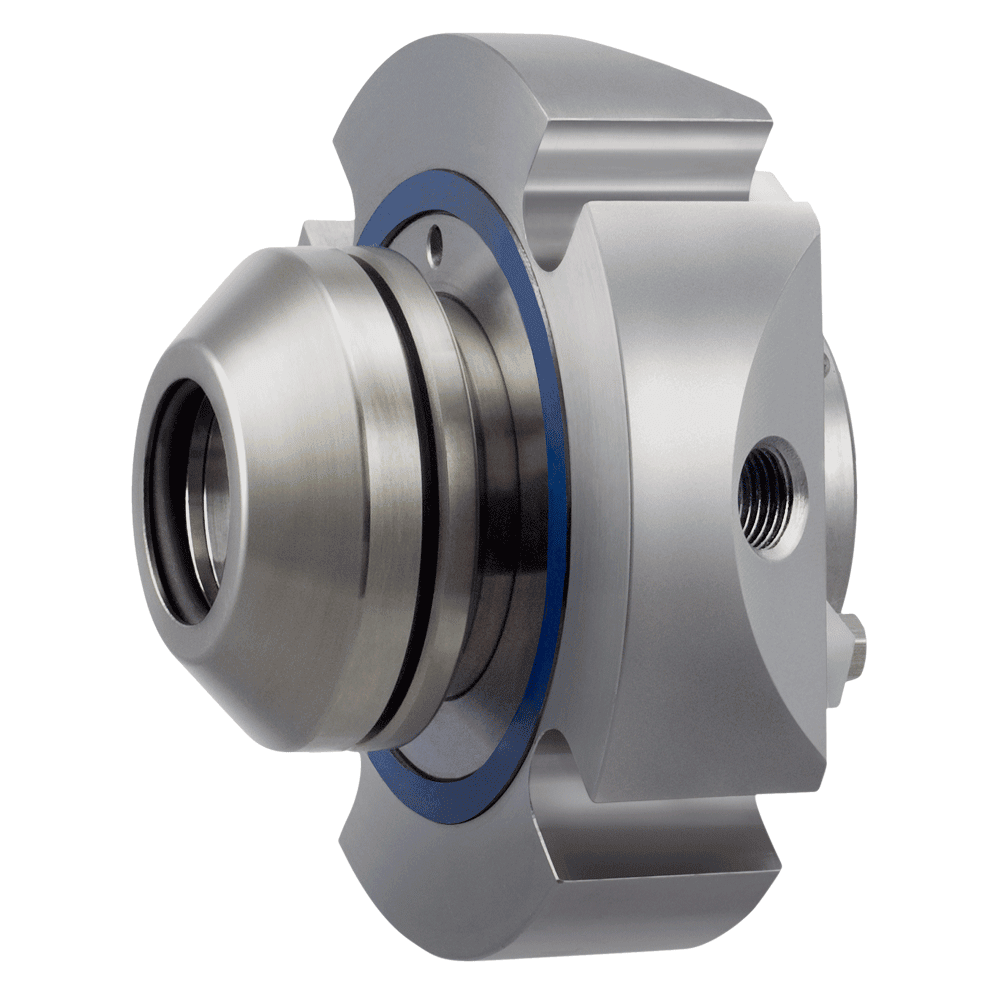

The delicate pharmaceutical sector requires the use of special mechanical seals on the processing machinery.

It is fundamental to maintain the high qualitative standard of the product and above all, to guarantee maximum functionality of the processing procedures.

Mechanical seals for pharmaceutical sector are designed in order to avoid the formation of deposits that could cause bacterial contamination of the medium (medicinal).

Huhnseal mechanical seals are also able to operate in totally dry conditions, with both abrasive and non-abrasive media and the typical flexibility requirements in terms of axial and radial run out of the agitator shafts are fully met.

Materials used for the mechanical seals for the Pharmaceutical applications are strictly Food-Grade.

MATERIALS OF MECHANICAL SEALS IN THE PHARMACEUTICAL SECTOR

- FDA, 3-A, USP Class VI, EG 1935 grades

- Carbon

- Dry running grade Carbon

- Silicon Carbide

- Silicon Carbide with Diamond Coating

- Tungsten Carbide

- EPDM

- HNBR

- Fluorelastomers

- Perfluorelastomers

- Stainless Steel

- Duplex Steel

- Coatings on metal parts

CHARACTERISTICS OF MECHANICAL SEALS IN THE PHARMACEUTICAL SECTOR

- Long life

- Great reliability

- Hygienic design

- Dry running possibility

- Seal faces not in contact with medium

- Double seals with buffer sealing water

APPLICATIONS OF MECHANICAL SEALS IN THE PHARMACEUTICAL SECTOR

- Vertical and horizontal agitators

- Mixers

- Centrifugal pumps

- Volumetric pumps

- Centrifugal separators