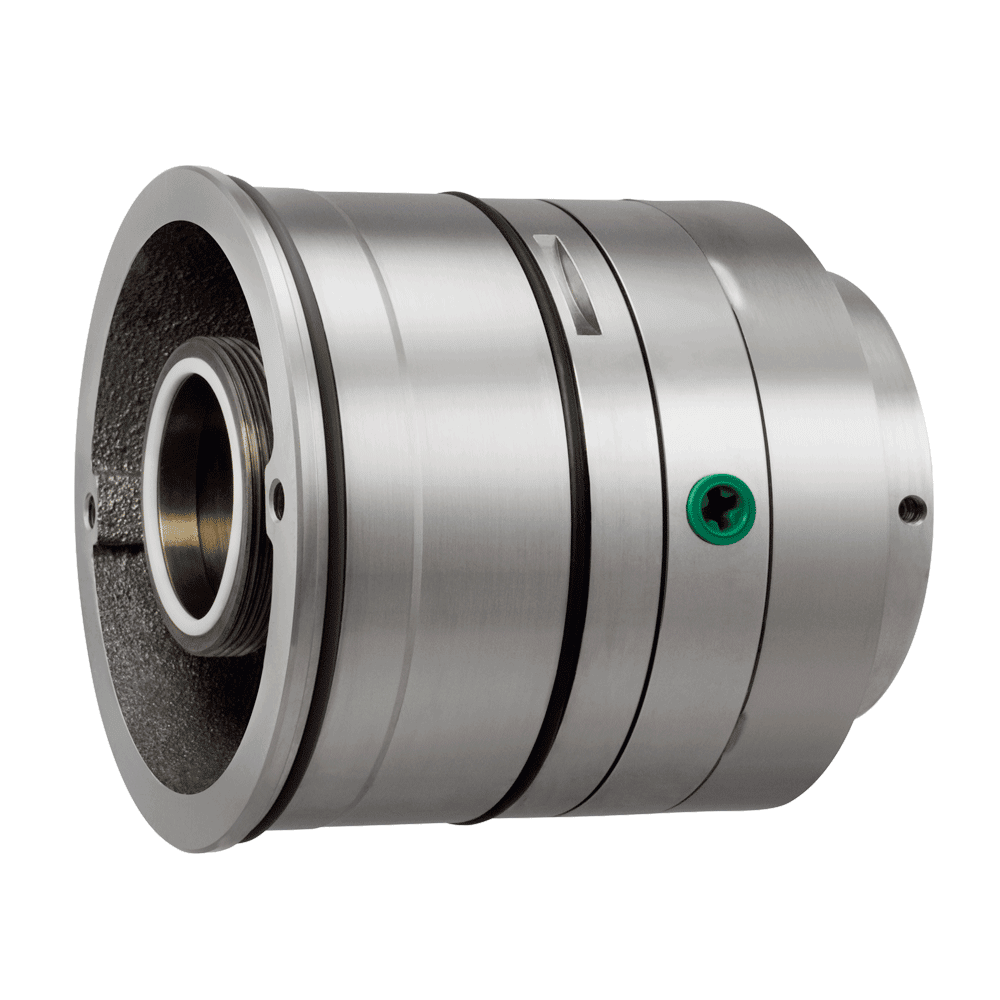

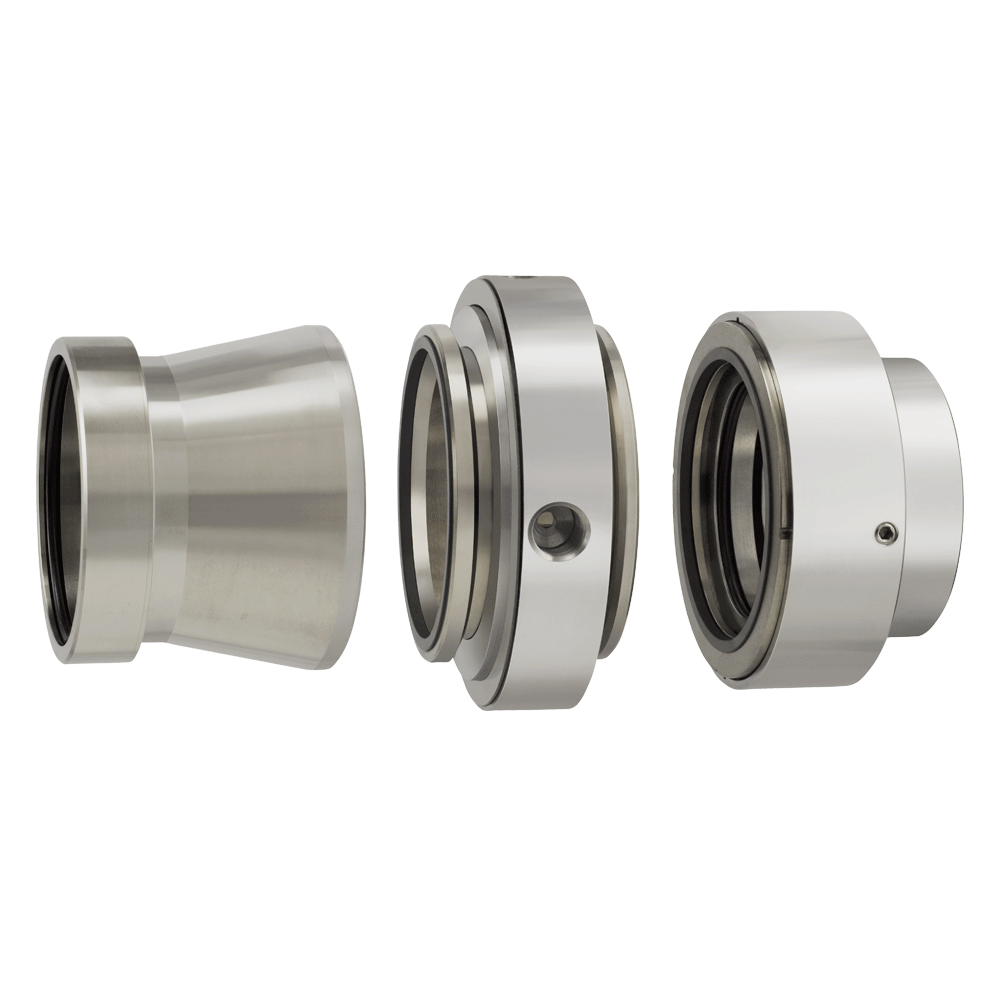

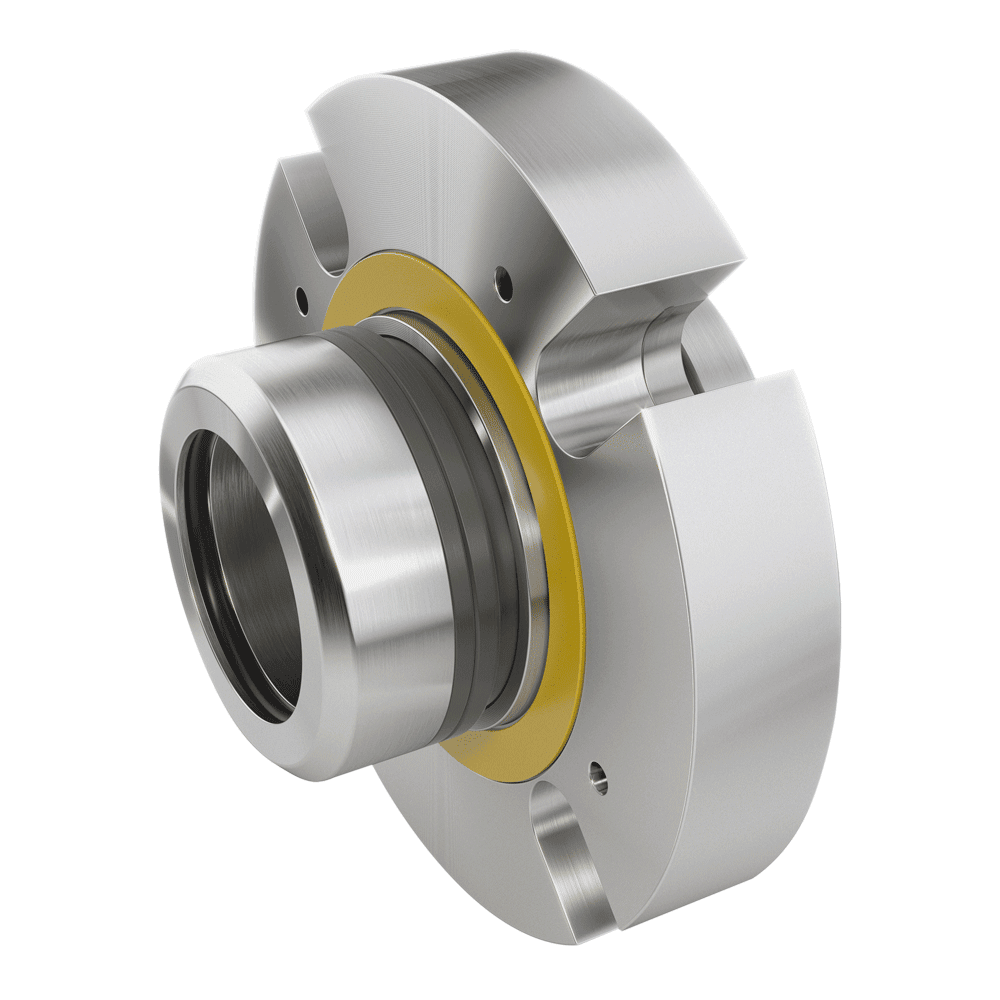

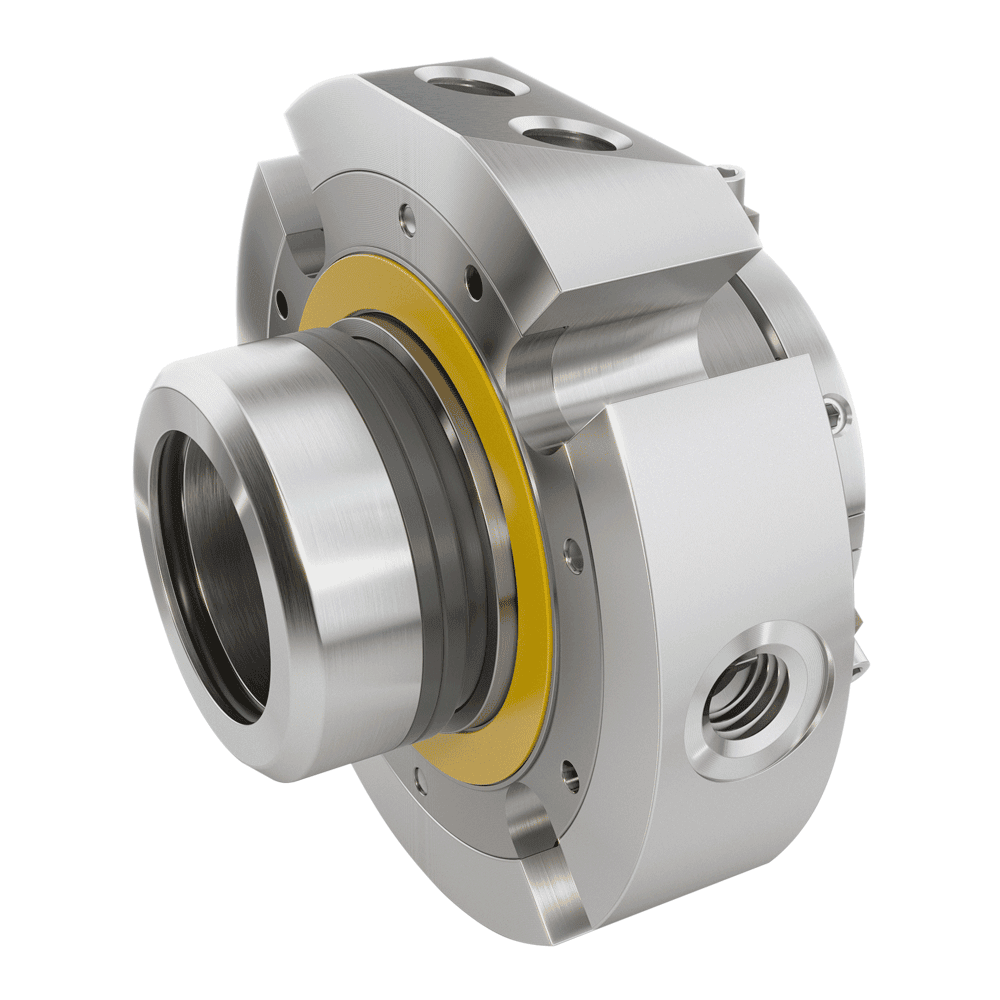

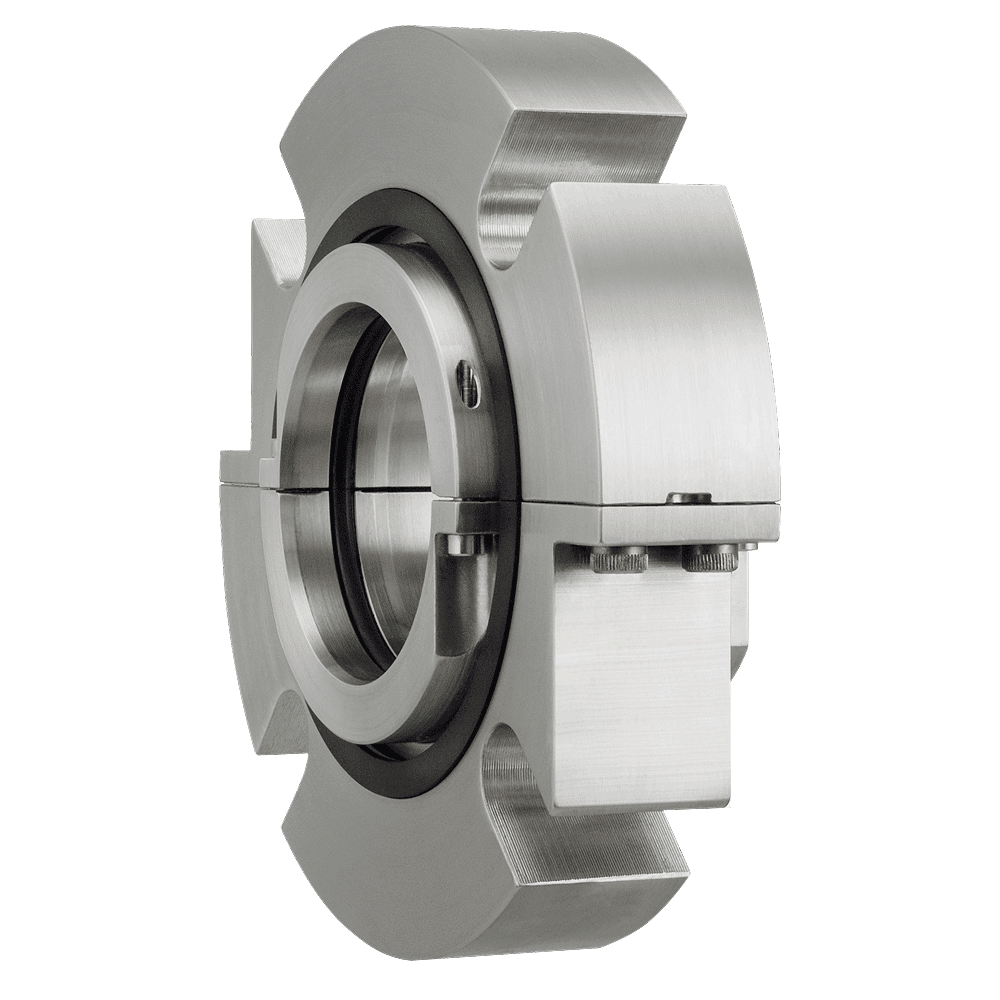

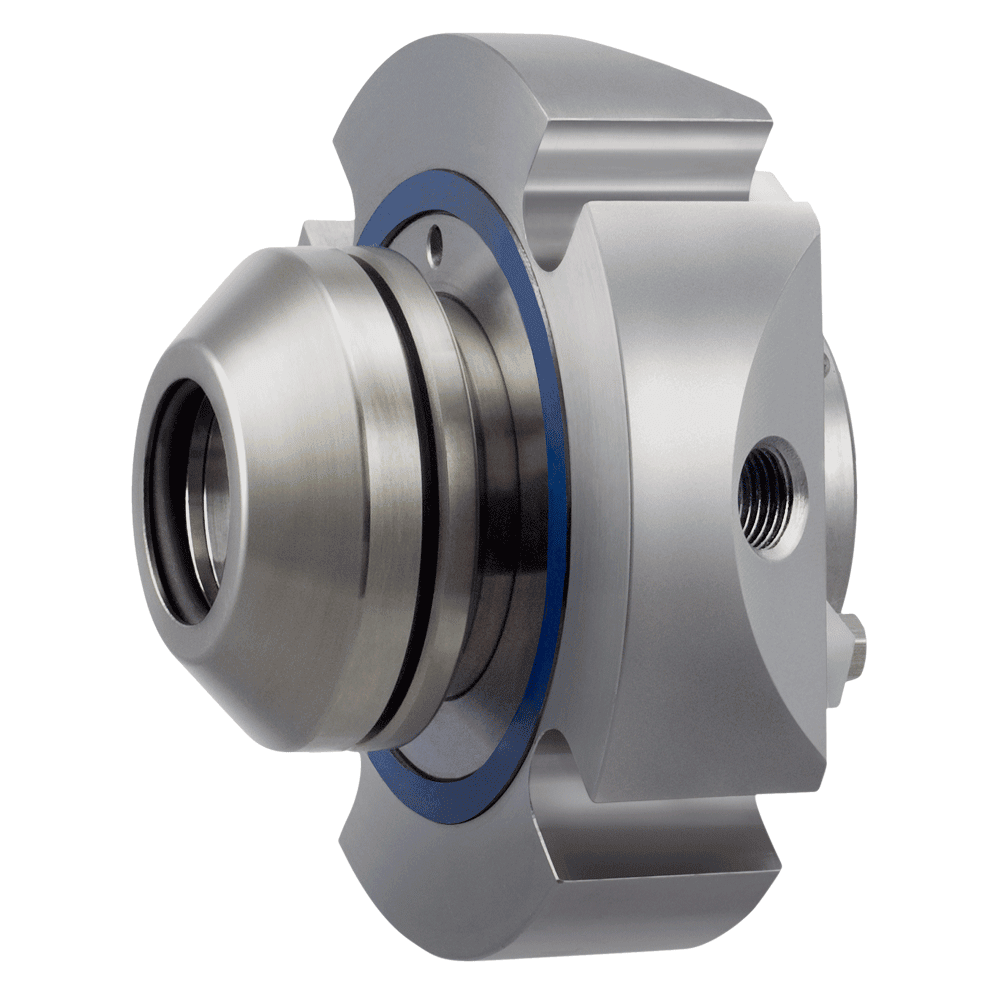

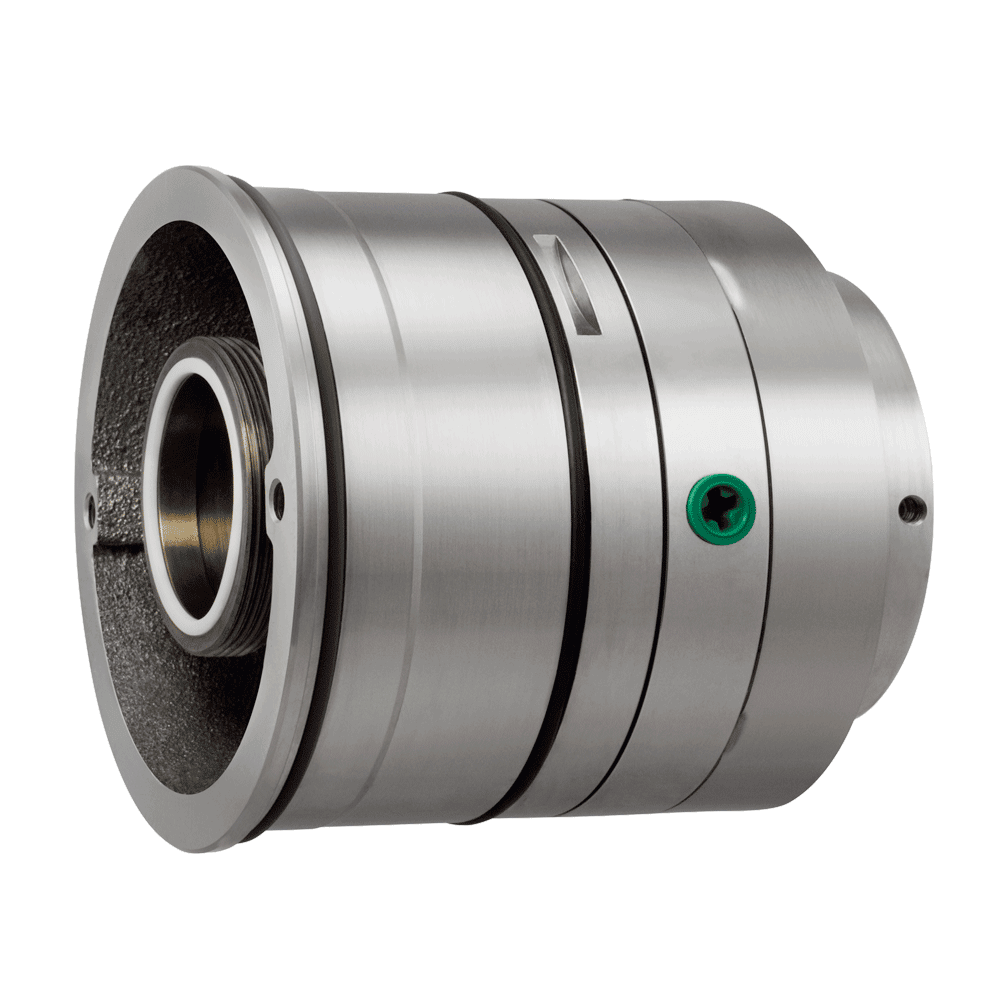

The mechanical seal is a critical component when it comes to reaching a high level of availability of rotating equipment.

Our goal is to offer the best possible sealing solution for pulp & paper industry and hereby increase the availability of process, reduce water and energy consumption and hence lower the total cost.

We achieve this by not only offering high quality mechanical seals but also establishing a strong and durable partnership where we focus on customers’ needs and priorities.

We help to standardize the sealing program, reduce the number of different seal types and lower you stock levels.

Our program spans from a strong standard seal range to highly specialized seals for demanding applications.

With Huhnseal vast application knowledge we can help to gain increased accessibility to process with improved profitability and quality, while at the same time lowering its energy and environmental impact.

MATERIALS OF MECHANICAL SEALS IN THE PULP & PAPER

- Carbon

- Silicon Carbide

- Silicon Carbide with Diamond Coating

- Tungsten Carbide

- EPDM

- Fluorelastomers

- Perfluorelastomers

- PTFE Encapsulated elastomers

- Stainless Steel

- Duplex Steel

- Titanium

CHARACTERISTICS OF MECHANICAL SEALS IN THE PULP & PAPER

- High resistance

- Long life

- Great reliability

- Water saving

- Power saving

- Easy to be repaired

APPLICATIONS OF MECHANICAL SEALS IN THE PULP & PAPER

- Medium Consistency Pumps

- Cooking Pumps for chemical pulp mills

- Centrifugal and volumetric process pumps

- Agitators and mixers

- Screens

- Refiners

- Pulpers

- Feeders

- Biomass equipment